Materials

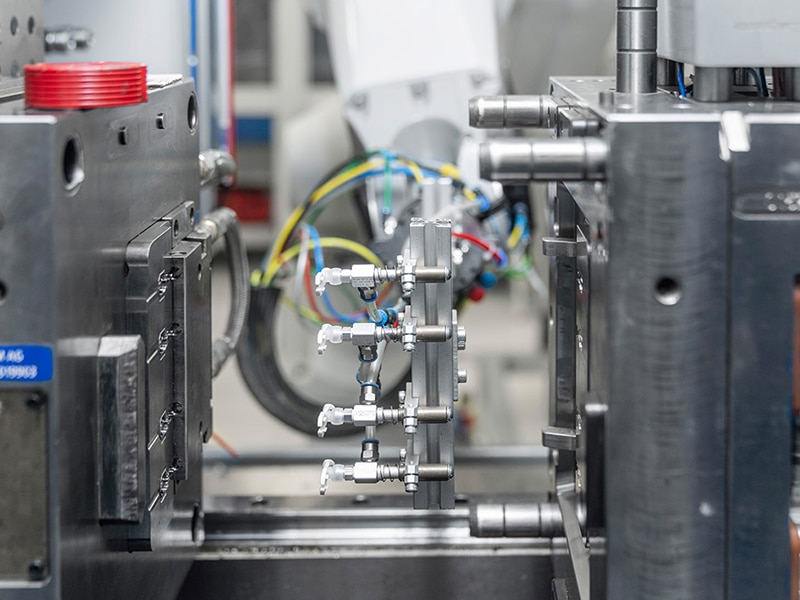

Injection Molding Service

Our Injection Molding Materials

ABS

PC

PA

PP

PMMA

POM

LDPE

HDPE

PVC

PTFE

PC/ABS

PS

NR

NBR

CR

SBR

EPDM

Silicone

FKM

FFKM

IIR

TPE

TPU

TPV

ABS

Acrylonitrile Butadiene Styrene

ABS Injection Molding is a manufacturing process where Acrylonitrile Butadiene Styrene (ABS) plastic is melted and injected into a mold to create parts with high precision and strength. ABS is a tough, durable thermoplastic commonly used for products that need to withstand impact and stress, such as automotive components, consumer electronics, and household goods. The injection molding process ensures efficient mass production with consistent quality, offering versatility in design, easy post-processing (like painting), and a cost-effective solution for high-volume production.

The key advantages of ABS injection molding include its excellent strength-to-weight ratio, impact resistance, and ease of customization. It is widely favored across industries for producing reliable, high-performance components.

PC

Polycarbonate

Polycarbonate (PC) material is a high-performance plastic widely used in injection molding for producing durable, transparent, and impact-resistant parts. Known for its excellent strength, optical clarity, and heat resistance, PC is ideal for applications requiring both mechanical durability and visual appeal. It is commonly used in industries like automotive, electronics, medical devices, and consumer goods, where parts need to withstand high temperatures and physical stress.

Injection molding with PC offers advantages such as precise molding of complex shapes and tight tolerances, making it a preferred material for producing high-quality, intricate components.

PA

Polyamide

Polyamide (PA), commonly known as Nylon, is a highly versatile thermoplastic material used extensively in injection molding. Known for its excellent mechanical properties, such as high strength, toughness, and wear resistance, PA is ideal for producing durable parts in automotive, electrical, and industrial applications. It also offers good resistance to chemicals, oils, and abrasion, making it suitable for components that undergo continuous wear or operate in harsh environments.

In injection molding, PA allows for the creation of complex, high-precision parts with excellent surface finish and dimensional stability. Its ability to be reinforced with glass fibers or other additives enhances its strength and rigidity.

PP

Polypropylene

Polypropylene (PP) is a commonly used thermoplastic material in injection molding due to its lightweight, durable, and chemical-resistant properties. It is highly resistant to acids, bases, and organic solvents, making it ideal for applications in industries such as automotive, packaging, medical, and consumer goods. PP also offers low moisture absorption and excellent fatigue resistance, which contributes to the material’s longevity and reliability in various applications.

In injection molding, PP is easy to process, offering good flow characteristics and high molding efficiency. It can be molded into a wide range of complex shapes with fine details.

PMMA

Polymethyl Methacrylate

PMMA (Polymethyl Methacrylate), often referred to as acrylic or acrylic glass, is a transparent thermoplastic known for its excellent optical clarity, UV stability, and high impact resistance. It is widely used in injection molding to create clear and durable components, making it ideal for applications in automotive, lighting, signage, medical devices, and consumer products.

In injection molding, PMMA can be processed easily, offering good flowability and the ability to create intricate, high-quality parts. It can be molded into complex shapes with precise detail and a glossy finish.

POM

Polyoxymethylene

POM (Polyoxymethylene), also known as acetal, is a versatile engineering plastic commonly used in injection molding for parts requiring high strength, low friction, and excellent dimensional stability. It offers outstanding mechanical properties, such as high stiffness, durability, and resistance to wear. POM is also highly resistant to solvents, oils, and fuels, which enhances its reliability in demanding industrial environments.

In injection molding, POM allows for the production of complex, high-precision components with tight tolerances and smooth surface finishes. Its excellent flow characteristics make it easy to process, resulting in efficient production cycles.

LDPE

Low-Density Polyethylene

LDPE is a widely used thermoplastic polymer characterized by its lightweight, flexible, and durable properties. LDPE is derived from the polymerization of ethylene monomers, resulting in a material that exhibits a low density of approximately 0.917 to 0.930 g/cm³, and has a relatively low melting point, making it easy to mold into a variety of shapes.

In injection molding, LDPE is ideal for producing parts like containers, bottles, films, and tubing. Its low-cost and ease of processing make it a popular choice for high-volume manufacturing.

HDPE

High-Density Polyethylene

HDPE (High-Density Polyethylene) is a versatile thermoplastic known for its high strength-to-density ratio, making it ideal for injection molding applications that require durability and resistance to impact. It has excellent chemical resistance, low moisture absorption, and can perform well in outdoor environments. These properties make HDPE suitable for manufacturing a wide range of products, including containers, bottles, automotive parts, and pipes.

In injection molding, HDPE is favored for its ease of processing and ability to produce parts with high stiffness and excellent impact resistance. It is highly efficient in mass production due to its fast cycle times and ability to be molded into complex shapes.

PVC

Polyvinyl Chloride

PVC (Polyvinyl Chloride) is a widely used thermoplastic material in injection molding due to its versatility, durability, and ease of processing. It comes in two primary forms: rigid and flexible. Rigid PVC is commonly used for pipes, fittings, and profiles, while flexible PVC is used for applications requiring elasticity, such as cables and flooring. PVC is resistant to chemicals, abrasion, and weathering, making it an ideal material for a broad range of industrial applications.

In injection molding, PVC offers excellent dimensional stability and the ability to mold complex shapes with high precision. It is highly cost-effective and can be easily processed, which makes it suitable for high-volume production.

PTFE

Polytetrafluoroethylene

PTFE (Polytetrafluoroethylene) is a high-performance plastic known for its exceptional chemical resistance, low friction properties, and high thermal stability. It is commonly used in injection molding for applications that demand superior performance in harsh environments, such as in the chemical, pharmaceutical, and food processing industries.

In injection molding, PTFE can be challenging to process due to its high melting point and low flowability, requiring specialized equipment and techniques. However, once molded, PTFE components offer excellent durability, low friction, and resistance to corrosion and electrical conductivity.

PC/ABS

Polycarbonate/Acrylonitrile Butadiene Styrene

PC+ABS (Polycarbonate + Acrylonitrile Butadiene Styrene) is a versatile thermoplastic blend commonly used in injection molding due to its balanced combination of strength, durability, and ease of processing. The material combines the impact resistance and high strength of polycarbonate with the rigidity and ease of molding of ABS, making it ideal for applications that require both toughness and smooth surface finishes.

In injection molding, PC+ABS can be molded into complex shapes with tight tolerances and fine detail. The blend is widely used in industries such as automotive, electronics, and consumer goods, where durable yet lightweight components are necessary.

PS

Polystyrene

Polystyrene (PS) is a thermoplastic material widely used in injection molding for producing rigid, transparent parts with excellent clarity. It is known for its ease of processing, affordability, and ability to create intricate shapes with precise detail. PS is commonly used in applications where transparency is important, such as in packaging, disposable cutlery, and cosmetic containers, due to its crystal-clear finish.

In injection molding, PS is ideal for high-volume production of simple and lightweight parts. It offers good dimensional stability and can be easily molded into complex designs.

NR

Natural Rubber

Natural Rubber (NR), is also used in injection molding for producing high-performance, flexible components. It boasts excellent elasticity, superior tensile strength, and resilience, making it ideal for applications that demand high stretchability and durability. NR exhibits outstanding wear resistance and is highly resistant to abrasion, which makes it well-suited for products subjected to repetitive stress and harsh environments.

In injection molding, NR is melted and injected into molds under high pressure, allowing for precise control over the part’s shape and dimensions. This process is ideal for manufacturing complex parts with intricate features and smooth surfaces.

NBR

Nitrile Butadiene Rubber

NBR commonly known as nitrile rubber, is widely used in injection molding due to its excellent oil, fuel, and chemical resistance. It offers superior mechanical properties, such as high tensile strength, excellent abrasion resistance, and low compression set, making it ideal for applications in automotive, industrial, and sealing products.

In injection molding, NBR is heated to its molten form and injected into precise molds to create complex, durable parts with consistent dimensions. The material’s excellent molding characteristics allow for the production of intricate designs and high-precision parts, such as O-rings, seals, gaskets, and hoses.

CR

Chloroprene Rubber

CR is also known as Neoprene, is a synthetic rubber that offers excellent resistance to heat, oil, chemicals, and weathering. When used in injection molding, CR provides high flexibility and superior durability, making it an ideal choice for products exposed to harsh conditions. Its resistance to environmental factors like ozone and UV degradation further enhances its suitability for applications in automotive, industrial, and electrical industries.

In the injection molding process, CR is heated until it reaches a molten state, then injected into a mold cavity to form the desired shape. The material’s high-flow characteristics and ability to retain its properties under stress allow for the production of precise.

SBR

Styrene-Butadiene Rubber

SBR (Styrene-Butadiene Rubber) is a synthetic rubber commonly used in injection molding for producing durable, high-performance parts. It offers excellent abrasion resistance, flexibility, and good aging properties, making it suitable for applications where toughness and long service life are required.

In injection molding, SBR rubber is used to create parts such as seals, gaskets, and automotive components. Its low-cost production process, combined with its strength and resilience, makes SBR a popular choice for a wide range of industrial applications.

EPDM

Ethylene Propylene Diene Monomer

EPDM (Ethylene Propylene Diene Monomer) rubber is commonly used in injection molding due to its excellent resistance to heat, ozone, and weathering. It remains flexible and durable even under extreme temperatures, ranging from -40°F to 275°F, making it suitable for a variety of automotive, electrical, and industrial applications.

In injection molding, EPDM rubber is used to manufacture seals, gaskets, and rubber components for high-performance applications. Its resistance to aging, water, and steam ensures long-lasting functionality, especially in outdoor and harsh environments.

Silicone

Silicone Rubber

Silicone rubber is a highly flexible and durable material used in injection molding to produce a wide range of products. Known for its excellent heat resistance, flexibility, and electrical insulation properties, it is ideal for applications requiring high performance in extreme conditions. Silicone rubber maintains its properties even at high temperatures and resists aging, UV exposure, and ozone damage.

In injection molding, silicone rubber is commonly used to manufacture seals, gaskets, medical devices, and electrical components. Its unique combination of high elasticity and low compression set ensures long-lasting performance. The material is also biocompatible, which makes it suitable for medical and food-grade applications.

FKM

Fluoroelastomer

FKM rubber (fluorocarbon rubber) is widely used in injection molding for applications requiring exceptional resistance to high temperatures and aggressive chemicals. It can withstand temperatures from -40°C to 250°C and offers outstanding protection against oils, fuels, acids, and solvents. FKM’s durability and high resilience ensure it performs well under extreme conditions, where other materials might fail.

In injection molding, FKM is often used to create precise, high-quality components such as seals, gaskets, O-rings, and other parts that require superior chemical and thermal resistance.

FFKM

Perfluoroelastomer

FFKM (Perfluoroelastomer) rubber is a premium material known for its exceptional resistance to extreme temperatures, aggressive chemicals, and high-pressure environments. It combines the elasticity of rubber with the chemical and thermal resistance of fluoropolymers. FFKM remains stable even in environments involving strong acids, bases, solvents, and high temperatures ranging from -20°C to 325°C.

In injection molding, FFKM is used to create precision parts such as seals, gaskets, O-rings, and custom components that demand high performance and durability.

IIR

Isobutylene isoprene rubber

IIR (Butyl Rubber) is a synthetic rubber renowned for its excellent impermeability to gases and moisture. It offers outstanding resistance to heat, UV light, ozone, and chemicals, which contributes to its longevity and reliability in harsh environments. Its excellent damping properties also make it suitable for applications requiring vibration absorption and noise reduction.

In injection molding, IIR butyl rubber is used to produce precise, durable parts like seals, gaskets, and flexible components. The material’s high elasticity and low compression set allow it to maintain its shape and functionality over time, even under extreme conditions.

TPE

Thermoplastic Elastomer

TPE (Thermoplastic Elastomer) is a versatile material that combines the flexibility of rubber with the ease of processing typical of plastics. It is known for its excellent elasticity, weather resistance, and ability to be molded at high temperatures. It is also recyclable, making it an eco-friendly choice for many applications.

In injection molding, TPE is a popular choice for producing parts that require soft-touch surfaces, impact resistance, and flexibility, such as seals, grips, and gaskets. Its thermoplastic nature allows it to be easily molded into complex shapes, offering excellent precision and cost-effectiveness.

TPU

Thermoplastic Polyurethane

TPU is a highly flexible and durable material known for its excellent abrasion resistance, tensile strength, and impact resistance. It combines the processing advantages of thermoplastics with the elastic properties of rubber, making it ideal for a wide range of applications, including automotive parts, footwear, medical devices, and electronics. TPU offers good chemical resistance, low-temperature flexibility, and high wear resistance, which makes it suitable for both industrial and consumer products.

TPV

Thermoplastic Vulcanizate

TPV is a high-performance material that combines the processing ease of thermoplastics with the rubber-like properties of vulcanized rubber. TPV is created by blending vulcanized rubber particles with a thermoplastic resin, giving it excellent flexibility, durability, and resistance to heat, oils, chemicals, and weathering. It is known for its high strength, good abrasion resistance, and low compression set, making it ideal for demanding applications such as automotive seals, gaskets, hoses, and electrical connectors. TPV’s ability to be processed using traditional thermoplastic molding techniques while maintaining the properties of rubber makes it a versatile material for a variety of industries.

Compression Molding Service

Our Compression Molding Materials

PTFE

PTFE (Polytetrafluoroethylene) is widely used in compression molding due to its excellent chemical resistance, high thermal stability, and low friction properties. It is an ideal material for creating components that need to perform in demanding environments, such as in chemical processing, electrical, and food industries. Compression molding of PTFE allows for the production of parts like seals, gaskets, and bearings that can withstand extreme temperatures and corrosive substances without degradation.

The material’s non-stick characteristics ensure that molded parts resist wear and friction, making them suitable for high-performance applications.

UHMWPE

UHMWPE (Ultra-High Molecular Weight Polyethylene) is one of the toughest plastic materials available, providing exceptional impact resistance and excellent performance in extreme environments. UHMWPE is highly resistant to chemicals, moisture, and abrasion, making it ideal for applications in industries like manufacturing, mining, and food processing.

In compression molding, UHMWPE can be molded into complex shapes with precise dimensions, offering excellent consistency in part performance. The material is able to maintain structural integrity under heavy loads, and have good self-lubricating properties.

NR

Natural Rubber (NR), is a highly versatile material widely used in compression molding for producing durable and flexible parts. Known for its excellent elasticity, resilience, and abrasion resistance, NR is ideal for applications that require high flexibility and tensile strength. It also offers good resistance to wear, tear, and environmental conditions.

In compression molding, NR is heated and compressed into molds to form parts with complex shapes and fine details. This process ensures uniformity and consistency in the final product, making it efficient for large-scale production.

NBR

NBR commonly known as nitrile rubber, is a synthetic rubber known for its excellent resistance to oils, fuels, and chemicals. NBR’s key properties include superior resistance to oil, grease, and petroleum-based products, making it particularly valuable in the automotive, industrial, and oil and gas industries.

The compression molding process involves placing the NBR compound into a heated mold where it is compressed to take the shape of the mold cavity, ensuring precise and consistent part production. This method is ideal for manufacturing parts that require tight tolerances and complex shapes.

CR

CR commonly known as Neoprene, is a synthetic rubber with excellent weather, ozone, and aging resistance. It is widely used in compression molding due to its versatile properties, including good flexibility, high tensile strength, and resistance to oil, heat, and chemicals. CR is especially valuable in applications that require durability in challenging environments, such as automotive, electrical insulation, and marine products.

The material’s excellent flow characteristics allow for compression molding of complex and durable parts, such as gaskets, seals, and protective covers. Neoprene is able to maintain its physical properties over time, even under exposure to environmental stressors.

SBR

SBR (Styrene-Butadiene Rubber) is a synthetic rubber commonly used in compression molding for manufacturing durable and cost-effective parts. It offers excellent resistance to abrasion, aging, and heat, making it ideal for applications requiring toughness and longevity.

In compression molding, SBR rubber is used to produce components such as seals, gaskets, and automotive parts. Its versatility and ease of processing enable efficient production of high-quality molded products that meet strict specifications for performance and durability.

EPDM

EPDM (Ethylene Propylene Diene Monomer) rubber is commonly used in compression molding for applications requiring excellent weather, ozone, and UV resistance. It maintains its flexibility and durability even under extreme temperatures, from -40°F to 275°F, making it ideal for outdoor and automotive applications.

In compression molding, EPDM rubber is used to create seals, gaskets, weather strips, and hoses. Its resistance to aging, water, and steam makes it a preferred material for industries such as automotive, construction, and electronics, ensuring long-lasting and reliable performance in demanding environments.

Silicone

Silicone rubber is a high-performance material commonly used in compression molding due to its excellent thermal stability, flexibility, and electrical insulation properties. It can withstand a wide temperature range from -100°F to 500°F, making it ideal for both high and low temperature applications. Silicone rubber is also highly resistant to UV, ozone, and weathering, ensuring long-term durability in outdoor and harsh environments.

In compression molding, silicone rubber is often used to create seals, gaskets, and custom parts for industries such as automotive, medical, and consumer electronics. Its biocompatibility, non-toxic nature, and ability to maintain flexibility make it a popular choice for critical applications, where high performance and safety are essential.

FKM

FKM rubber, also known as fluorocarbon rubber, is a high-performance material often used in compression molding for applications requiring exceptional chemical resistance and high-temperature performance. FKM rubber can withstand temperatures ranging from -40°C to 250°C and offers excellent resistance to oils, fuels, solvents, and aggressive chemicals.

In compression molding, FKM rubber is commonly used for seals, gaskets, O-rings, and other components that need to endure harsh conditions. FKM rubber’s resilience to high pressures, extreme temperatures, and corrosive substances ensures reliable performance and durability, even in the most demanding environments.

FFKM

FFKM is an advanced synthetic rubber known for its unparalleled chemical resistance and high-temperature stability, capable of withstanding extreme conditions up to 327°C, and offers excellent resistance to oils, fuels, solvents, and aggressive chemicals.

In compression molding, FKM rubber is commonly used for seals, gaskets, O-rings, and other components that need to endure harsh conditions. The material’s low permeability to gases and excellent aging properties make it ideal for long-lasting, high-performance parts.

IIR

IIR (Butyl Rubber) is a synthetic rubber known for its excellent air and moisture impermeability, making it an ideal choice for sealing applications. It is highly resistant to chemicals, UV light, and oxidation, which makes it suitable for use in harsh environments.

In compression molding, IIR butyl rubber is used to create durable, high-quality components like seals, gaskets, and vibration dampeners. The material’s ability to withstand extreme temperatures and its flexibility make it perfect for molding complex shapes with tight tolerances.

CNC Machining Service

Our CNC Machining Materials

ABS

Acrylonitrile Butadiene Styrene

ABS CNC Machining involves using computer-controlled machines to cut, shape, and finish Acrylonitrile Butadiene Styrene plastic into precise parts. This method is ideal for creating custom prototypes, functional parts, and complex geometries that require high accuracy and tight tolerances. ABS offers good impact resistance, durability, and excellent surface finish, making it suitable for a wide range of industries, including automotive, consumer electronics, and medical.

CNC machining with ABS ensures efficient production with minimal material waste. It’s particularly useful for low to medium-volume production, providing flexibility in design changes and high repeatability.

PC

Polycarbonate

Polycarbonate (PC) is a strong, transparent plastic known for its high impact resistance, optical clarity, and heat tolerance, making it a popular choice for CNC machining. It is widely used in applications that require durability and clarity, such as in the automotive, medical, and electronics industries. Despite being a tough material, PC remains relatively easy to machine, allowing for precise and complex shapes to be created with high accuracy.

When PC is CNC machined, it offers excellent dimensional stability and can be processed with tight tolerances. Its versatility allows it to be used for both structural and aesthetic components.

PA

Polyamide

Polyamide (PA), or Nylon, is a popular material in CNC machining due to its excellent balance of strength, flexibility, and wear resistance. It is lightweight, has high mechanical strength, and offers good impact resistance, making it suitable for parts that need to withstand harsh conditions. PA also has low friction properties, which is advantageous for components like gears, bearings, and other moving parts in machinery.

In CNC machining, PA can be easily machined to tight tolerances, producing high-quality parts with smooth finishes. With good chemical resistance and the ability to withstand repeated stress, PA is a reliable choice for producing durable, high-performance components.

PP

Polypropylene

PMMA

Polymethyl Methacrylate

PMMA (Polymethyl Methacrylate), also known as acrylic, is a versatile thermoplastic known for its excellent optical clarity, impact resistance, and UV stability. When used in CNC machining, PMMA is easy to machine, allowing for the creation of intricate, high-precision parts with a smooth surface finish. Its transparency and ability to be polished to a clear, glossy surface make it an ideal material for applications in industries like automotive, signage, medical devices, and electronics.

CNC machining of PMMA offers advantages such as high-dimensional accuracy and the ability to produce complex geometries with tight tolerances.

POM

Polyoxymethylene

POM (Polyoxymethylene), also known as acetal, is a high-performance engineering thermoplastic widely used in CNC machining for its exceptional mechanical properties. Known for its low friction, high stiffness, and excellent dimensional stability, POM is commonly used for parts that require high wear resistance and durability, it also offers excellent resistance to solvents, fuels, and lubricants, making it suitable for a wide range of industrial applications.

In CNC machining, POM is prized for its ease of machining, allowing for the production of precise, high-quality parts with tight tolerances. It can be easily milled, turned, and drilled to create complex geometries and smooth finishes.

LDPE

Low-Density Polyethylene

LDPE is a widely used thermoplastic polymer characterized by its lightweight, flexible, and durable properties. LDPE is derived from the polymerization of ethylene monomers, resulting in a material that exhibits a low density of approximately 0.917 to 0.930 g/cm³, and has a relatively low melting point, making it easy to mold into a variety of shapes.

In injection molding, LDPE is ideal for producing parts like containers, bottles, films, and tubing. Its low-cost and ease of processing make it a popular choice for high-volume manufacturing.

HDPE

High-Density Polyethylene

HDPE (High-Density Polyethylene) is a durable, strong, and stiff thermoplastic commonly used in CNC machining for applications that require impact resistance and chemical stability. With its higher density compared to LDPE, HDPE offers greater strength, rigidity, and resistance to wear. It is ideal for manufacturing parts that need to withstand harsh environments, such as outdoor exposure, chemical contact, or high-impact conditions.

In CNC machining, HDPE is often used to produce components like piping systems, tanks, valves, and structural parts for industries such as construction, automotive, and water management. Its relatively low friction coefficient and ease of machining make it suitable for creating precise and functional parts.

PVC

Polyvinyl Chloride

PVC (Polyvinyl Chloride) is a versatile plastic material commonly used in CNC machining due to its excellent machinability and durability. It is available in both rigid and flexible forms, with rigid PVC being more commonly machined for applications requiring strength and stability. PVC is resistant to chemicals, abrasion, and environmental factors, making it ideal for use in industries such as construction, automotive, and medical devices. Its low cost and ease of processing also make it a preferred choice for many CNC machining projects.

In CNC machining, PVC can be precisely cut, drilled, and shaped to meet complex specifications. Its high dimensional stability and ability to be easily machined into intricate parts make it suitable for custom components.

PTFE

Polytetrafluoroethylene

PTFE (Polytetrafluoroethylene) is a highly versatile material known for its excellent chemical resistance, low friction, and high-temperature stability, making it ideal for CNC machining. Its unique non-stick properties and ability to resist harsh chemicals and extreme temperatures make it an ideal choice for parts used in industries such as chemical processing, pharmaceuticals, and food manufacturing.

Despite its challenging properties, such as being relatively soft and prone to expansion when heated, PTFE can be successfully machined using specialized equipment. CNC machining offers high precision and the ability to produce complex geometries, making it ideal for custom parts that require tight tolerances.

PS

Polystyrene

Polystyrene (PS) is a lightweight, rigid thermoplastic often used in CNC machining for applications where clarity, ease of processing, and cost-effectiveness are key. While it is not as durable as other plastics like ABS or polycarbonate, its excellent machinability allows it to be easily cut, drilled, and shaped into detailed parts. PS is commonly used for prototypes, consumer products, and small components that do not require high strength or impact resistance.

In CNC machining, PS is typically used for low-stress applications such as electronic housings, displays, and protective covers. It offers good dimensional stability and a smooth finish.

MC Nylon

MC Nylon

MC Nylon is a high-performance material frequently used in CNC machining for manufacturing durable, precision-engineered components. Known for its excellent wear resistance, low friction, and high strength, MC Nylon is particularly effective in applications that require parts to withstand heavy loads, impact, and abrasive conditions.

In CNC machining, MC Nylon is commonly used to create gears, bearings, bushings, and structural components that need to perform under demanding conditions. Its ability to be machined with fine tolerances and its versatility in terms of shape and size make MC Nylon a preferred material for custom parts that require long-lasting durability and reliable performance.

UHMWPE

Ultra-High Molecular Weight Polyethylene

UHMWPE is a highly durable material used in CNC machining for applications requiring exceptional wear resistance and low friction. Due to its high molecular weight, UHMWPE provides outstanding impact resistance, making it ideal for manufacturing parts that endure heavy wear and tear. It also exhibits excellent chemical and moisture resistance, which makes it suitable for use in industries such as mining, food processing, and aerospace.

When machined via CNC, UHMWPE can be shaped into precise parts with tight tolerances. CNC machining allows for the creation of complex geometries with consistent results.

Aluminum

Aluminum

Aluminum is a lightweight, corrosion-resistant metal known for its excellent strength-to-weight ratio and versatility. It is widely used across various industries, including automotive, aerospace, construction, and packaging, due to its ease of fabrication, high durability, and thermal and electrical conductivity. Aluminum also has good resistance to oxidation, making it ideal for both indoor and outdoor applications.

Additionally, it is highly recyclable, making it an environmentally friendly material choice. Whether in the form of sheets, extrusions, or castings, aluminum is valued for its performance, aesthetic appeal, and cost-effectiveness.

Stainless Steel

Stainless Steel

Stainless steel is a highly durable and corrosion-resistant alloy composed primarily of iron, carbon, and chromium. Known for its strength, versatility, and resistance to staining, rust, and oxidation, stainless steel is widely used in industries such as automotive, aerospace, food processing, medical devices, and construction. It maintains its appearance and integrity even in harsh environments, making it ideal for both functional and aesthetic applications. Available in various grades, stainless steel can be tailored for specific needs, offering excellent mechanical properties, hygiene, and long-term reliability.

Carbon Steel

Carbon Steel

Carbon steel is a strong and durable material made primarily of iron and carbon, with varying carbon content that influences its hardness, strength, and flexibility. It is widely used in construction, manufacturing, automotive, and machinery due to its affordability, versatility, and ability to withstand high stress and impact. Carbon steel is available in several grades, ranging from low-carbon steel (soft and malleable) to high-carbon steel (hard and brittle), making it suitable for a broad range of applications. While it is prone to corrosion, it can be treated or coated to enhance its durability in different environments.

Copper

Copper

Copper is a highly conductive metal known for its excellent electrical and thermal conductivity, making it essential in electrical wiring, electronics, and heat exchangers. It is also valued for its corrosion resistance, malleability, and ductility, which allow it to be easily shaped and formed into various products. Copper is widely used in plumbing, roofing, and industrial applications due to its durability and natural antimicrobial properties. Its ability to develop a protective patina over time adds to its aesthetic appeal and longevity, especially in outdoor and architectural uses.

Brass

Brass

Brass is an alloy primarily composed of copper and zinc, known for its strength, durability, and attractive gold-like appearance. It is highly malleable and resistant to corrosion, making it ideal for applications in plumbing, electrical components, musical instruments, and decorative items. Brass also offers excellent machinability, making it easy to work with in manufacturing processes. With its good conductivity and resistance to rust and tarnishing, brass is commonly used in both functional and ornamental applications, providing a combination of aesthetics and performance.

Cast Molding Service

Our Cast Molding Materials

PU

Polyurethane

Polyurethane (PU) is commonly used in urethane cast molding due to its excellent flexibility, durability, and ability to mimic various hardness levels. It can be formulated to be soft or rigid, making it suitable for a wide range of applications, from automotive parts to medical devices. PU castings offer good resistance to abrasion, tear, and impact, making them ideal for parts that will be exposed to wear and mechanical stress.

In urethane cast molding, PU is typically used for creating prototypes, low-volume production parts, and customized components. The material is highly customizable in terms of color, texture, and finish, offering manufacturers the ability to meet specific design requirements.

MC Nylon

MC Nylon

MC Nylon is commonly used in cast molding. Known for its excellent mechanical properties, MC Nylon offers superior wear resistance, high strength, and low friction characteristics. It is especially effective in applications where parts are subject to heavy loads, high stress, or abrasive environments. MC Nylon’s toughness and impact resistance make it ideal for producing components that require long service life and reliable performance under demanding conditions.

In cast molding, MC Nylon is often used to manufacture precision components such as gears, bearings, bushings, and other high-performance parts.

Related Resources

Manufacturing Processing Guide Compression Molding Guide This compression molding guide is designed to describe all

Manufacturing Processing Guide Injection Molding Guide This injection molding guide is designed to describe all

In today’s fast-paced market, businesses are constantly seeking ways to improve supply chain efficiency. A

Contact us

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

If you are interested in our products, you can leave us a message via the form below and we will get back to you within 8 hours!