Custom Cast Molding for Precision Components

What is Cast Molding

Cast molding is a process where liquid materials like urethane or nylon are poured into molds to create durable parts with specific properties. It’s an excellent choice for producing strong, wear-resistant parts that require intricate shapes, offering a reliable solution for industries from automotive to consumer goods.

Our urethane cast molding services deliver parts with outstanding durability, flexibility, and resistance to impact and abrasion. Ideal for prototypes and production parts alike, urethane cast molding supports projects that require consistent performance, even under demanding conditions.Cast Molding Technique Specifiactions

| Service | Details |

|---|---|

| Process Materials | Plastics and rubber, including custom sourcing, see material list below |

| Standard Finishes | SPI and VDI |

| Mold Service | DFM report and mold flow analysis |

| Mold Ownership | Customer owned with mold maintenance |

| Mold Cavities | Single or multi-cavities |

| Mold Life | Unlimited (If the mold worn out, Erye will cover the cost of new mold) |

Cast Molding Capabilitie

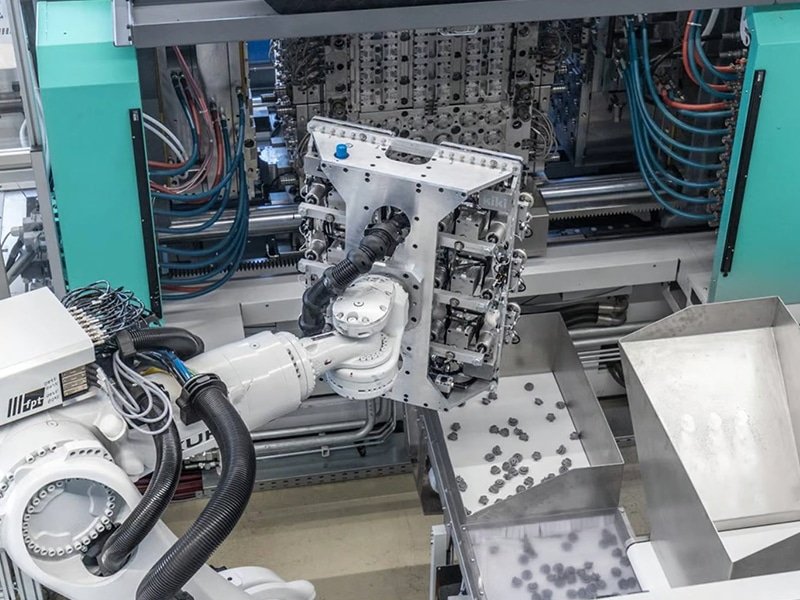

Plastic Injection Molding

Rubber Injection Molding

Additional Molding Options

How to Work with Us

Gallery of Cast Molding Parts

Advantages of Cast Molding with Us

Exceptional Durability and Strength

Intricate Design Capabilities

Cost-Effective for Large Parts

Injection Molding Applications

Injection Molding FAQs

There are many factors that determine the cost of injection molding your custom parts. The three main expenses are tooling, materials and production.

Related Resources of Injection Molding

Manufacturing Processing Guide Compression Molding Guide This compression molding guide is designed to describe all

Manufacturing Processing Guide Injection Molding Guide This injection molding guide is designed to describe all

In today’s fast-paced market, businesses are constantly seeking ways to improve supply chain efficiency. A