Compression Molding Service for Molded Rubber Parts

Compression Molding Service

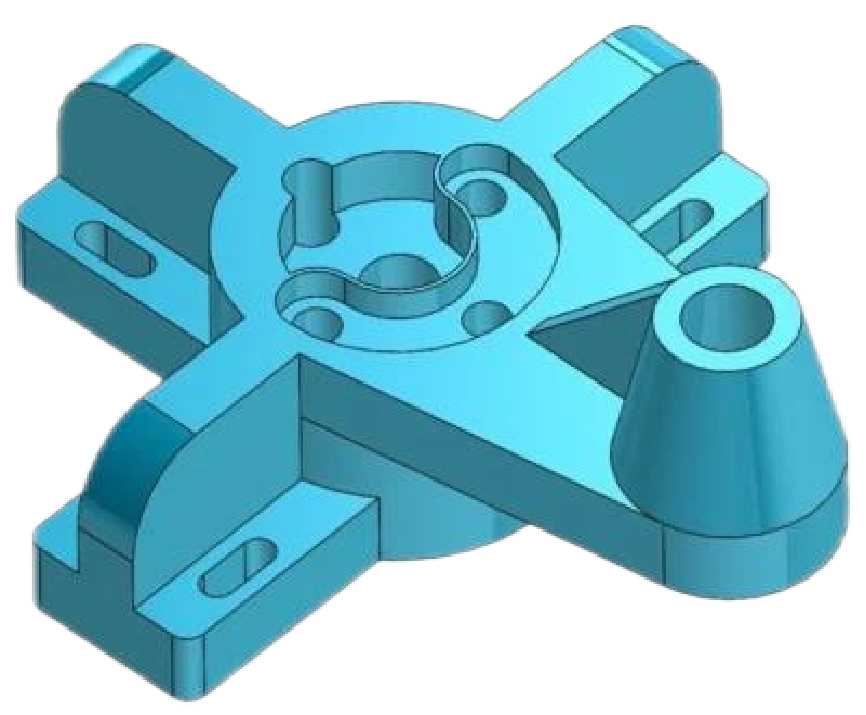

Compression molding is an ideal process for producing large, high-strength molded parts with intricate designs. The process begin with placing the preheated material, typically a thermoset plastic or rubber, into a heated mold cavity. The the mold is closed, and the high pressure forces the material to comform to the shape of the mold, creating the desired shape compression molding products.

Our facility is equipped with over 30 sets of compression molding machines, capable to handle various materials, part sizes, and production volume. Erye engineering team will support you from custom design to prototyping and mass production.Compression Molding Service Specifications

| Service | Details |

|---|---|

| Process Materials | Most rubbers, PTFE and UHMWPE, including custom sourcing, see material list below |

| Standard Finishes | SPI and VDI |

| Minimum Wall Thickness | To maintain structural integrity, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

| Maximum Part Dimensions | Our largest molding machine can process parts within 2500x2000mm. |

| Mold Service | DFM report and mold flow analysis |

| Mold Ownership | Customer owned with mold maintenance |

| Mold Cavities | Single or multi-cavities |

| Mold Life | Unlimited (If the mold worn out, Erye will cover the cost of new mold) |

Compression Molding Products

Rubber Compression Molding

Plastic Compression Molding

Silicone Compression Molding

PTFE Compression Molding

UHMW Compression Molding

Additional Rubber Molding Options

Materials for Compression Molding Products

Silicone

EPDM

NR

NBR

CR

SBR

IIR

FKM

FFKM

UHMWPE

PTFE

Silicone

Silicone Rubber

Silicone rubber is a high-performance material commonly used in compression molding due to its excellent thermal stability, flexibility, and electrical insulation properties. It can withstand a wide temperature range from -100°F to 500°F, making it ideal for both high and low temperature applications. Silicone rubber is also highly resistant to UV, ozone, and weathering, ensuring long-term durability in outdoor and harsh environments.

In compression molding, silicone rubber is often used to create seals, gaskets, and custom parts for industries such as automotive, medical, and consumer electronics. Its biocompatibility, non-toxic nature, and ability to maintain flexibility make it a popular choice for critical applications, where high performance and safety are essential.

EPDM

Ethylene Propylene Diene Monomer

EPDM (Ethylene Propylene Diene Monomer) rubber is commonly used in compression molding for applications requiring excellent weather, ozone, and UV resistance. It maintains its flexibility and durability even under extreme temperatures, from -40°F to 275°F, making it ideal for outdoor and automotive applications.

In compression molding, EPDM rubber is used to create seals, gaskets, weather strips, and hoses. Its resistance to aging, water, and steam makes it a preferred material for industries such as automotive, construction, and electronics, ensuring long-lasting and reliable performance in demanding environments.

NR

Natural Rubber

Natural Rubber (NR), is a highly versatile material widely used in compression molding for producing durable and flexible parts. Known for its excellent elasticity, resilience, and abrasion resistance, NR is ideal for applications that require high flexibility and tensile strength. It also offers good resistance to wear, tear, and environmental conditions.

In compression molding, NR is heated and compressed into molds to form parts with complex shapes and fine details. This process ensures uniformity and consistency in the final product, making it efficient for large-scale production.

NBR

Nitrile Butadiene Rubber

NBR commonly known as nitrile rubber, is a synthetic rubber known for its excellent resistance to oils, fuels, and chemicals. NBR’s key properties include superior resistance to oil, grease, and petroleum-based products, making it particularly valuable in the automotive, industrial, and oil and gas industries.

The compression molding process involves placing the NBR compound into a heated mold where it is compressed to take the shape of the mold cavity, ensuring precise and consistent part production. This method is ideal for manufacturing parts that require tight tolerances and complex shapes.

CR

Chloroprene Rubber

CR commonly known as Neoprene, is a synthetic rubber with excellent weather, ozone, and aging resistance. It is widely used in compression molding due to its versatile properties, including good flexibility, high tensile strength, and resistance to oil, heat, and chemicals. CR is especially valuable in applications that require durability in challenging environments, such as automotive, electrical insulation, and marine products.

The material’s excellent flow characteristics allow for compression molding of complex and durable parts, such as gaskets, seals, and protective covers. Neoprene is able to maintain its physical properties over time, even under exposure to environmental stressors.

SBR

Styrene-Butadiene Rubber

SBR (Styrene-Butadiene Rubber) is a synthetic rubber commonly used in compression molding for manufacturing durable and cost-effective parts. It offers excellent resistance to abrasion, aging, and heat, making it ideal for applications requiring toughness and longevity.

In compression molding, SBR rubber is used to produce components such as seals, gaskets, and automotive parts. Its versatility and ease of processing enable efficient production of high-quality molded products that meet strict specifications for performance and durability.

IIR

Isobutylene isoprene rubber

IIR (Butyl Rubber) is a synthetic rubber known for its excellent air and moisture impermeability, making it an ideal choice for sealing applications. It is highly resistant to chemicals, UV light, and oxidation, which makes it suitable for use in harsh environments.

In compression molding, IIR butyl rubber is used to create durable, high-quality components like seals, gaskets, and vibration dampeners. The material’s ability to withstand extreme temperatures and its flexibility make it perfect for molding complex shapes with tight tolerances.

FKM

Fluoroelastomer

FKM rubber, also known as fluorocarbon rubber, is a high-performance material often used in compression molding for applications requiring exceptional chemical resistance and high-temperature performance. FKM rubber can withstand temperatures ranging from -40°C to 250°C and offers excellent resistance to oils, fuels, solvents, and aggressive chemicals.

In compression molding, FKM rubber is commonly used for seals, gaskets, O-rings, and other components that need to endure harsh conditions. FKM rubber’s resilience to high pressures, extreme temperatures, and corrosive substances ensures reliable performance and durability, even in the most demanding environments.

FFKM

Perfluoroelastomer

FFKM is an advanced synthetic rubber known for its unparalleled chemical resistance and high-temperature stability, capable of withstanding extreme conditions up to 327°C, and offers excellent resistance to oils, fuels, solvents, and aggressive chemicals.

In compression molding, FKM rubber is commonly used for seals, gaskets, O-rings, and other components that need to endure harsh conditions. The material’s low permeability to gases and excellent aging properties make it ideal for long-lasting, high-performance parts.

UHMWPE

Ultra-High Molecular Weight Polyethylene

UHMWPE (Ultra-High Molecular Weight Polyethylene) is one of the toughest plastic materials available, providing exceptional impact resistance and excellent performance in extreme environments. UHMWPE is highly resistant to chemicals, moisture, and abrasion, making it ideal for applications in industries like manufacturing, mining, and food processing.

In compression molding, UHMWPE can be molded into complex shapes with precise dimensions, offering excellent consistency in part performance. The material is able to maintain structural integrity under heavy loads, and have good self-lubricating properties.

PTFE

Polytetrafluoroethylene

PTFE (Polytetrafluoroethylene) is widely used in compression molding due to its excellent chemical resistance, high thermal stability, and low friction properties. It is an ideal material for creating components that need to perform in demanding environments, such as in chemical processing, electrical, and food industries. Compression molding of PTFE allows for the production of parts like seals, gaskets, and bearings that can withstand extreme temperatures and corrosive substances without degradation.

The material’s non-stick characteristics ensure that molded parts resist wear and friction, making them suitable for high-performance applications.

Compression Molding Surface Finishing Standard

SPI A: Glossy Finish

Provides a highly reflective surface, ideal for aesthetic applications such as consumer products.

- Price Range: $$$

- SPI Finish Grades: SPI A1, A2, A3

SPI B: Semi-Gloss Finish

Offers a moderate sheen, balancing gloss and matte, suitable for parts needing some visual appeal without being overly shiny.

- Price Range: $$

- SPI Finish Grades: SPI B1, B2, B3

SPI C: Matte Finish

Features a non-reflective surface that reduces glare, often used for functional parts where aesthetics are less critical.

- Price Range: $

- SPI Finish Grades: SPI C1, C2, C3

SPI D: Textured Finish

Enhances grip and durability, commonly applied to functional components to improve handling and reduce wear.

- Price: $

- SPI Finish Grades: SPI D1, D2, D3

01

Send Drawings & Get a Quote

02

DFM & Mold Production

03

Sample Confirmation

04

Production & Quality Check

Advantages of Compression Molding with Us

Complex Geometries and Large Part Sizes

Flexible Production Volumes

Tailored Rubber Formulas

Compression Molding Applications

Compression Molding FAQs

Share your part design, including CAD files, material requirements, and expected quantities. Contact us directly via email or our website to start your quote process!

When placing an order that requires tooling, the lead time typically depends on the complexity of the mold and design requirements. As rubber molding manufacturers, Erye offer full service from mold to production, we aim to deliver tools within 4-6 weeks for most projects. For simpler tools, the timeline may be shorter, while more intricate or large-scale molds may require additional time. We provide a detailed schedule after reviewing your project specifications to ensure transparency and on-time delivery.

Once you pay for the tooling, the ownership of the mold tooling typically transfers to you, the customer. We shall not use the mold by ourselves without permission from the customer.

Erye has more than 100 sets of machines for rubber molding production, including both compression molding machine and injection molding machine. Generally, each molding press allows for several hundreds of molded pars per day.

Related Resources of Rubber Molding Manufacturers

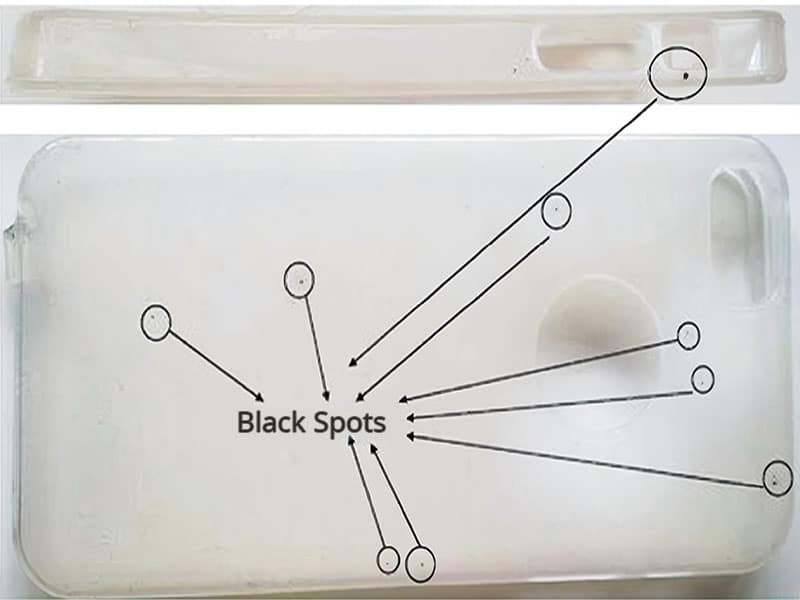

Black spots on plastic, and black specks are common visual defects in injection molding, appearing

Burn marks in injection molding appear as dark or black discolorations, often at the end

What is the Meaning of Warpage Plastic warpage deformation, often seen as twisting or distortion,