Innovative Manufacturing Solutions for the Aerospace Industry

At Erye, we specialize in producing high-performance components tailored to the aerospace sector's stringent demands. From lightweight parts to precision-engineered components, we ensure quality, reliability, and compliance with industry standards.

Comprehensive Engineering Support from Prototype to Production

At Erye, our custom manufacturing process is guided by engineering expertise, ensuring every stage meets the highest standards of quality and functionality.

01

Initial Design Consultation

Our engineering team collaborates with you to understand your product requirements, including functional needs, environmental conditions, and material preferences. We provide detailed feedback and suggestions to refine your designs for manufacturability.

02

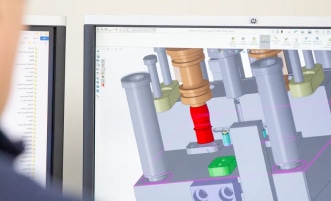

Prototyping & Testing

Using advanced prototyping methods like 3D printing, CNC machining, or soft tooling, we create functional prototypes to validate designs. Our engineer analyze these prototypes, perform tests for tensile strength, environmental durability, and fit to fine-tune the design for its specific application.

03

DFM (Design for Manufacturability) Analysis

We optimize designs through DFM reports, identify potential issues like undercuts, thin walls, or complex geometries. Suggestions for mold design, parting lines, or draft angles are provided to streamline production. This step reduces lead times, minimizes costs, and ensures that your design is ready for efficient mass production.

04

Material Selection Assistance

Leveraging our deep material knowledge, we guide you in choosing the ideal materials. Our engineer team evaluates your part's operating conditions, including temperature extremes, mechanical loads, chemical exposure, and UV resistance to recommend materials, helping you choose the best options.

Additionaly, we assist with specialty material formulations to meet unique demands, such as flame resistance or high-impact applications, ensuring optimal results for your project.

Additionaly, we assist with specialty material formulations to meet unique demands, such as flame resistance or high-impact applications, ensuring optimal results for your project.

05

Process Development & Quality Assurance

At Erye, we tailor our manufacturing processes to meet your specific production needs. For low-volume production, we prioritize flexibility with adaptable tooling solutions. For high-volume runs, we optimize cycle times and part consistency using automation and advanced monitoring systems.

Quality assurance is deeply integrated into every stage. Engineers closely monitor critical parameters like temperature, pressure, and cycle time during production. Advanced inspection equipment, such as Coordinate Measuring Machines (CMMs), ensures dimensional accuracy and precision. This dual focus on efficiency and quality guarantees a flawless output for every part.

Quality assurance is deeply integrated into every stage. Engineers closely monitor critical parameters like temperature, pressure, and cycle time during production. Advanced inspection equipment, such as Coordinate Measuring Machines (CMMs), ensures dimensional accuracy and precision. This dual focus on efficiency and quality guarantees a flawless output for every part.

Manufacturer Capabilities for Aerospace Industry

Injection Molding

Flexibility in design, high-quality materials, and scalable production.

Compression Molding

Producing complex shapes with exceptional rubber material strength and consistency.

Take a Closer Look Cast Molding

Producing low-to-medium volume and intricate customized parts.

Take a Closer Look CNC Machining

Precisely cut and shape materials to produce complex parts with tight tolerances.

Take a Closer Look Mold & Tooling

Mold design, material selection, precision machining, and quality testing to deliver durable, high-performance molds.

Take a Closer Look Assembly Service

Ensures precise integration of components, optimizing design, quality, and functionality for assembly final products.

Take a Closer Look

Why Company Choose Us

Erye stands out as a trusted manufacturer due to our deep understanding of its unique challenges and demands. We offer end-to-end custom manufacturing solutions, from design to mass production, with a strong focus on precision and durability. With a commitment to quality, cost efficiency, and customer collaboration, Erye ensures every part we manufacture meets the rigorous requirements.

Tailored Solutions for Tough Applications

At Erye, we understand the challenges in different industries, including heavy-duty equipment and harsh environments. We specialize in producing custom rubber and plastic components that withstand wear, weather, and chemical exposure.

Full-Service Manufacturing

From prototyping to mass production, we offer comprehensive services, including injection molding, compression molding, and CNC machining, ensuring precision and scalability for your components.

Material Expertise

We provide advanced material solutions, including customized rubber formulas and engineering-grade plastics, tailored to meet the performance requirements of your specific applications.

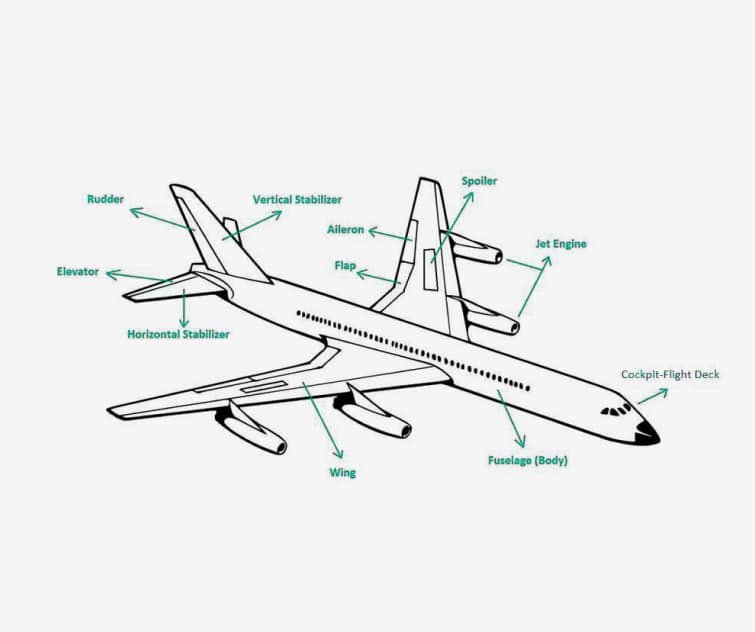

Applications of Aerospace Industry

- Wing panels

- Support brackets

- Turbine blades

- Engine housings

- Combustion chamber parts

- Hydraulic components

- Circuit board housings

- Electrical enclosures

- Seat supports

- Tray tables

- Decorative panels

- Valves and fittings

- Thermal insulation components

Other Custom Manufacturing Applications

Contact us

We provide professional products and technical services.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

+86 18000000000

sales@swcpu.com

+86 18000000000

Online Message

If you are interested in our products, you can leave us a message via the form below and we will get back to you within 8 hours!